Have you ever stood before a pile of logs, armed only with a traditional axe, and thought, “There has to be a better way”? This is the predicament that leads many to wonder: do firewood drill bits actually work? In our modern age, where efficiency and ease often drive innovation, the question of optimizing such a primal task as wood splitting is not only logical but increasingly relevant.

Do Firewood Drill Bits Work? Firewood drill bits, designed to attach to a standard drill, promise a simpler, less physically demanding method of splitting wood. They’re touted for their efficiency and safety, particularly for those not skilled in traditional wood chopping.

The lure of transforming a tough, sweat-inducing task into something more manageable is powerful. This blog aims to delve into the mechanics of firewood drill bits, evaluate their effectiveness, and explore their advantages and potential drawbacks. Whether you’re a seasoned wood splitter or a novice looking to prepare for your first winter, this article promises insights that could change the way you approach this age-old chore.

Types of Firewood Drill Bits

Differentiating Various Models and Designs

The diversity in models and designs of firewood drill bits is vast, catering to a range of drilling tasks. The spade bit, known for its flat, paddle-like shape, is ideal for quick, rough drilling. The auger bit, with its spiral design, excels in creating deep, clean holes in hardwood. Forstner bits are preferred for creating precise, flat-bottomed holes, while hole saws are used for larger circular cuts. Each design has distinct advantages and uses, making the choice of bit crucial depending on the project’s requirements.

Material Composition and Structural Variations

The effectiveness of a firewood drill bit is significantly influenced by its material composition and structural design. Most bits are made from high-speed steel (HSS) for durability and heat resistance, while others feature a carbide tip for enhanced cutting power. Some bits have a coated surface, such as titanium or black oxide, to reduce friction and increase longevity. The structural variations, such as the length, diameter, and tip design, also play a crucial role in determining the bit’s suitability for different drilling scenarios.

Suitability of Each Type for Specific Woods or Conditions

Selecting the right firewood drill bit is crucial for achieving desired results and depends largely on the type of wood and drilling conditions. Spade bits are ideal for softwoods and light projects, while auger bits are suited for hardwoods and deep drilling. Forstner bits are best for precision tasks in both hardwood and softwood. In wet or resinous woods, bits with anti-friction coatings are preferable to prevent clogging. Understanding the suitability of each type ensures efficient and safe drilling, reducing the risk of damage to both the tool and the wood.

Mechanics and Functionality to do firewood drill bits

How Firewood Drill Bits Work

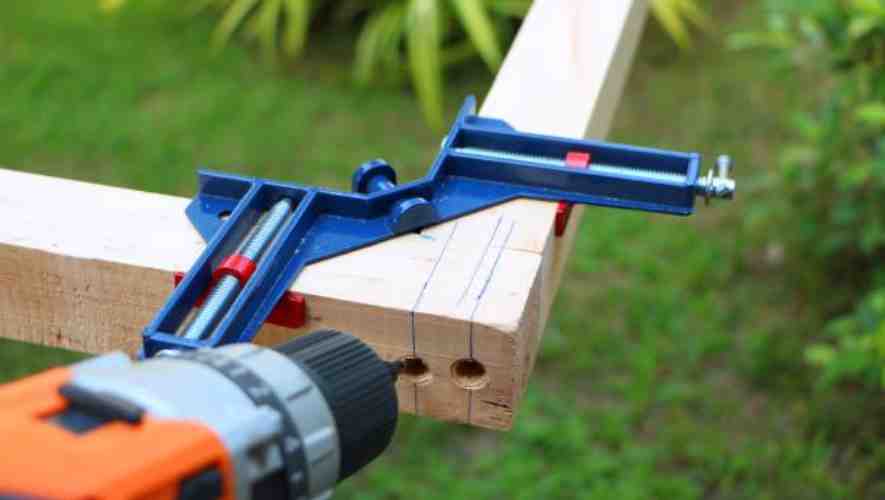

Firewood drill bits, specialized tools designed for splitting wood, operate on a simple yet effective principle. These bits attach to a standard drill and, when activated, rotate at high speeds. The unique design of the bit, often tapered and spiraled, allows it to penetrate the wood easily and exert outward pressure, causing the wood to split along its natural grain. This process significantly reduces the physical effort required compared to traditional methods, streamlining the wood splitting process for both professionals and hobbyists.

Technical Specifications and Operational Mechanisms

The efficiency of firewood drill bits lies in their technical design and operational mechanisms. Made from high-strength steel, these bits are durable and resistant to wear and tear. The key features include a pointed tip for easy insertion into the wood, and a spiraled or grooved shaft that aids in the splitting process. Sizes and shapes vary, accommodating different types of wood and splitting requirements. Compatibility with various drills also makes them versatile tools, adaptable to different power outputs and rotational speeds, enhancing their utility in diverse working conditions.

Efficiency and Performance Metrics

When evaluating the efficiency of firewood drill bits, several performance metrics are crucial. The speed of splitting, measured in the number of logs processed per hour, is a primary indicator of efficiency. The energy consumption of the drill bit, in relation to the volume of wood split, provides insight into its cost-effectiveness. Durability is another critical factor, determining the lifespan of the bit under regular usage. The ease of operation and the quality of the split, which should be clean and consistent with the grain of the wood, are also essential for user satisfaction.

Comparative Analysis to do firewood drill bits

Comparison with Conventional Firewood Splitting Techniques

Traditional firewood splitting methods, such as using an axe or a maul, have been the norm for centuries. These methods require significant physical effort and skill, with an emphasis on manual labor. In contrast, firewood drill bits, used with a powered drill, offer a more modern approach. This method reduces physical exertion and relies on the mechanical power of the drill, providing a more efficient and less labor-intensive experience. It’s important to consider that while drill bits offer ease, they also depend on the availability of power tools and a certain level of technical know-how.

Advantages and Disadvantages of Using Drill Bits

Utilizing drill bits for firewood splitting presents several advantages. The most prominent is the reduction in physical labor, which makes the process accessible to a broader range of users, including those with physical limitations.. Drill bits can often split wood more quickly than traditional methods, enhancing productivity. On the downside, this technique requires access to a power drill and the necessary drill bits, which can be a significant initial investment. The reliance on electricity or battery power can be a limitation in remote or off-grid locations.

Case Studies or Examples of Effective Usage

There are numerous real-world applications where firewood drill bits have shown their effectiveness. For instance, in a study conducted in rural communities, the introduction of drill bits for firewood splitting led to a substantial decrease in the time and effort required to prepare firewood, benefiting the elderly and those with physical limitations. In commercial firewood production, the adoption of drill bits has resulted in increased output and efficiency, demonstrating the potential of this technology in both small-scale and large-scale operations. These examples underscore the transformative impact of integrating modern tools into traditional practices.

Safety and Maintenance Considerations using firewood drill bits

Safety Guidelines for Using Firewood Drill Bits

When working with firewood drill bits, it’s imperative to adhere to strict safety protocols to prevent accidents and injuries. Always wear appropriate personal protective equipment, such as safety glasses, gloves, and hearing protection. Ensure that the drill bit is securely fitted into the drill, and check for any signs of damage or wear before use. Maintain a stable and balanced posture while drilling, and avoid forcing the bit into the wood, as this can cause slippage or breakage. Remember, safety should always be your foremost concern.

Maintenance and Care for Longevity

Proper maintenance of firewood drill bits extends their life and ensures optimal performance. After each use, clean the bits thoroughly to remove any wood residue or sap, as these can cause corrosion over time. Store the drill bits in a dry, cool place to prevent rusting. Regularly check for dullness, and sharpen the bits as needed to maintain efficient cutting ability. Lubricating the bits can also help reduce friction and wear during use. By taking these simple steps, you can significantly increase the lifespan of your firewood drill bits.

Common Issues and Troubleshooting Tips

Encountering issues with firewood drill bits is common, but many can be easily resolved. If the bit is not cutting efficiently, it may be due to dullness, requiring sharpening. When a bit gets stuck in the wood, avoid forcing it out; instead, gently reverse the drill to extract it. If you notice excessive heat buildup, it could be a sign of dullness or too much friction, indicating a need for lubrication or a break to let the bit cool down. Regular inspection for damage and adhering to proper usage techniques can help avoid many common problems.

Conclusion

Firewood drill bits offer a unique solution to wood splitting, combining ease of use with efficiency. They are particularly beneficial for those seeking a safer, less strenuous alternative to traditional methods.

In conclusion, firewood drill bits stand as a testament to human ingenuity in simplifying physical labor. For many, they represent a welcome departure from the back-breaking work of traditional wood chopping. It’s important to remember that while they offer convenience, they may not replace the traditional axe for everyone, purists or those splitting extremely large or hard logs. Ultimately, the decision to use a firewood drill bit depends on your individual needs, physical ability, and preference for tradition versus modernity. Whichever path you choose, may your fires burn bright and your labor be fulfilling