Choosing the right size drill bit for a number 10 screw is crucial for any DIY project or professional task. This decision not only affects the integrity of your work but also ensures the durability of the assembly. You might be wondering why it’s important to match the drill bit size precisely with a number 10 screw. The reason is simple yet significant: using the wrong size can lead to poor fitment, weakening of material, or even damage to the screw or the surface.

What size Drill bit for number 10 Screw? The ideal drill bit size for a number 10 screw is a 3/16 inch bit for softwood and a 7/32 inch bit for hardwood. This size ensures a snug fit for the screw, providing maximum holding power without stripping the material. By choosing the correct size, you ensure the screw fits perfectly, enhancing the stability and longevity of your project.

In this blog, we’ll delve into various aspects of choosing the right drill bit for a number 10 screw. Whether you’re a seasoned professional or a DIY enthusiast, understanding this will not only make your work easier but also elevate the quality of your projects. We’ll cover topics like different types of screws and drill bits, techniques for precise drilling, and additional tips to achieve the perfect fit. Stay tuned to learn more and enhance your skills in precision drilling.

Understanding Number 10 Screws

Number 10 screws, a popular fastener in various industries, are distinguished by specific dimensions and characteristics. These screws have a major diameter of 0.190 inches (4.83mm), making them robust for numerous applications.

The thread pitch, which is the distance between threads, varies between fine and coarse options, affecting their grip and strength in different materials. Their unique size offers a balance between the delicacy of smaller screws and the robustness of larger ones, making them versatile for use in medium-strength applications.

Number 10 screws are renowned for their versatility, finding utility in a wide range of applications. Commonly, they are used in woodworking, metalworking, and in the construction of electronics and appliances.

The materials used for these screws include stainless steel, brass, and aluminum, each offering different benefits. Stainless steel provides corrosion resistance, making it ideal for outdoor or moisture-prone environments. Brass screws are preferred for their aesthetic appeal and corrosion resistance, while aluminum screws are known for their light weight and resistance to rust.

The adaptability of number 10 screws is further enhanced by the variety of lengths and head types available. Lengths can range from a few millimeters to several inches, catering to different thicknesses and types of materials. The head types include flat, round, pan, and truss, each designed for specific purposes.

Flat head screws are ideal for countersinking, providing a flush surface, while round heads are more decorative and protrude slightly. Pan head screws offer a compromise between the two, and truss heads provide a larger surface area, reducing the risk of pulling through soft materials.

Drill Bits: Types and Sizes

Overview of Different Types of Drill Bits

Drill bits come in various types, each designed for specific purposes and materials. The twist drill bit is the most common, characterized by its helical shape and used for general drilling into metal, wood, and plastic.

Brad point drill bits, with their sharp point and wide flutes, are ideal for precise drilling in wood, reducing splintering and ensuring clean holes.

Spade drill bits, also known as paddle bits, feature a broad, flat blade and are used for making large holes in wood. Each type offers unique advantages, depending on the application.

Sizing of Drill Bits: Metric and Imperial Measurements

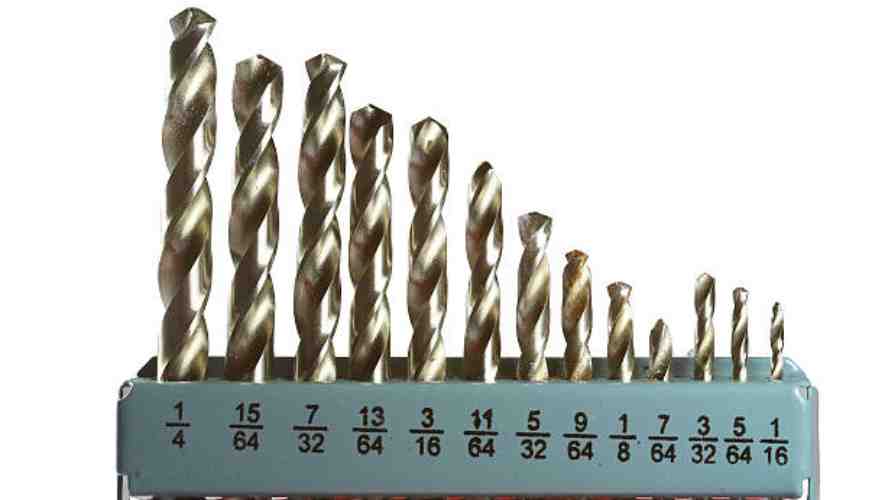

Drill bits are sized in both metric and imperial measurements, catering to different markets and standards. Metric sizes are measured in millimeters, providing a range from very fine to large diameters.

The imperial system, on the other hand, uses fractions of an inch to define the size of the drill bit. It’s essential for users to understand both systems, as certain projects or materials may require specific size measurements for optimal results. A comprehensive drill bit set typically includes a range of sizes in both metric and imperial units.

Factors Affecting Drill Bit Selection

The selection of the right drill bit is influenced by several factors, including the material being drilled, the type of screw used, and the required precision. For instance, drilling into metal requires a different bit type, such as cobalt or titanium-coated bits, compared to drilling into wood or plastic.

The screw type also matters; for example, a countersink drill bit is necessary for creating a conical seat for flathead screws. Additionally, precision tasks in woodworking or metalworking may demand specific drill bits designed for accuracy and clean finishes. Understanding these factors ensures efficient and effective drilling for various applications.

Selecting the Right Drill Bit for Number 10 Screws

General Guidelines for Matching Drill Bit Size to Screw Size

Choosing the correct drill bit for a screw is crucial for both the integrity of the workpiece and the effectiveness of the fastening. Generally, the drill bit diameter should match the inner diameter of the screw’s body, excluding the threads.

This ensures a snug fit for the screw, providing maximum strength and stability. For screws with a larger gauge, it’s important to incrementally increase the bit size accordingly, balancing a firm fit without compromising the material’s structure.

Specific Recommendations for Number 10 Screws

For number 10 screws, which are commonly used due to their robust size and strength, selecting the right drill bit is particularly important. Typically, a drill bit with a diameter of 1/8 inch (or 3.175 mm) is ideal for these screws.

This size allows the screw to anchor securely without causing undue stress on the material. It’s also important to consider the length of the screw and adjust the drilling depth accordingly, ensuring that the screw sits flush with or below the surface of the material.

Considerations for Material Type (Wood, Metal, Plastic)

Different materials require different approaches when drilling. For wood, a slightly smaller drill bit than the screw diameter can be used, as the material’s softness allows for expansion. In contrast, metal requires a more precise match to avoid thread damage or material weakening.

For plastic, caution is necessary to prevent cracking; a bit size equal to or slightly larger than the screw diameter is often best. In all cases, using sharp, well-maintained bits and appropriate drilling speeds is essential for optimal results.

Drilling Techniques and Best Practices

Step-by-step Guide on How to Drill for Number 10 Screws

Drilling for number 10 screws requires precision and understanding of the correct technique. Begin by selecting the appropriate drill bit size, typically a bit slightly smaller than the screw diameter for a snug fit.

Mark the drilling spot with a pencil or a small indentation using a punch tool, ensuring it’s accurately placed. While drilling, maintain a steady hand and apply consistent pressure, but avoid excessive force which could cause the bit to break.

As you reach the desired depth, slow down to prevent any sudden breakthrough that could damage the material.

Tips for Ensuring Accuracy and Avoiding Common Mistakes

Accuracy in drilling is paramount to avoid misaligned screws and potential damage to materials. Always use a sharp drill bit to ensure clean and precise holes. Before drilling, double-check measurements and markings, as even a small deviation can lead to significant errors.

Use a drill guide or a template for repetitive tasks to maintain consistency. Be mindful of the material you’re working with; softer materials require slower drilling speeds to prevent tear-out, while harder materials need a steady, more forceful approach.

Safety Precautions When Using Drill Bits and Handling Screws

Safety is crucial when working with drills and screws. Always wear protective gear, including safety glasses and gloves, to protect against flying debris and sharp edges. Ensure the drill has a secure grip and use clamps to hold the workpiece firmly in place.

Check the drill bits for any damage or wear before use, as a compromised bit can break under stress. When handling screws, be cautious of sharp edges and points. Keep your work area clean and free from loose screws and debris to prevent accidents.

Conclusion

Choosing the right drill bit size for a number 10 screw is essential for the success of any project. A 3/16 inch bit for softwood and a 7/32 inch bit for hardwood are the most suitable choices, ensuring a snug fit and optimal performance.

In conclusion, understanding the relationship between screw sizes and drill bit sizes is more than just a technical necessity; it’s a skill that can significantly impact the quality and durability of your work. Whether you’re hanging shelves, assembling furniture, or working on a custom project, using the right tools and techniques is key. Remember, the right drill bit size can make all the difference in achieving a professional and secure finish. So next time you pick up a number 10 screw, you’ll know exactly which drill bit to pair it with for the best results.